Cutting Plasterboard to size for ceilings and walls

Types of, uses and fixing sheets of Gyproc Plasterboard

|

Framed the walls & ceilings? Then you're ready to start cutting plasterboard to size and fixing it in place, ready for the plasterers to come in and finish it off (assuming the first fix plumbing and electrics have been completed!). Gyproc sheets either get flushed (tape & jointed) or skimmed with a thin layer of finish plaster. For flushing special boards with tapered edges are used, whereby the taper allows a space for the tape and jointing compound to sit into ready for sanding flat, hence the term 'flushing'. When being skimmed with a thin coat of plaster, flat boards are used, the joints still taped with a mesh tape but then the whole surface is plastered over. |

|

What tools are you cutting plasterboard with?

It's rarely the case in carpentry but for cutting plasterboard you don't need any expensive tools. If it's a one off or you are not going to be cutting plasterboard a lot, then all you need is an old handsaw (or plasterboard one), Stanley knife and a straight edge.

- An old handsaw, or an inexpensive one you don't mind ruining as plasterboard will take the edge off the teeth

- A Stanley knife and several spare blades

- A straight edge such as a long spirit level

- A surform is handy, which acts like a hand plane would for timber

- A battery drill and PH2 scredriver bits, along with specific plasterboard screws to screw the boards to the studs or joists

I probably wouldn't bother with this unless you cut alot of plasterboard, but because I do I've also got a Plasterboard T-Square as well.

Having this tool means rather than measuring across the board twice and marking two lines to join up with a straight edge, you only have to mark the board once when cutting to length. Place the square up to the line and you can score it perfectly across the board. It saves loads of set out time and means I get perfectly square cuts every time.

Special drywall hammers are available for fixing plasterboard too. They have a large milled face for extra grip on the nail heads and also have a sharp flat claw that can be used like an axe for quickly and accurately cutting plasterboard for electrical boxes and cables etc. Click here for loads more info on hammers.

These days it is more common to screw your plastebroard sheets to the wall/ceiling, which minimises the chances of 'popping' which is when the board moves but the nail or screw stays put, forcing the filler over the head to pop off and leave a hole that needs to be filled.

You can buy auto-feed screw-guns and collated screws to fix plasterboard, special drywall screw guns or just use an ordinary cordless drill with a plasterboard bit that has a depth stop that means you can quickly screw to the right depth each time.

Which side of the plasterboard do you cut?

Plasterboard is cut to length by first marking then scoring a line on the face side of the board with a straight edge and Stanley knife. Then, lift the sheet off the floor and snap the board along the score line.

Finally you run the knife down the other side of the board, cutting the back of the plasterboard backing sheet.

The joints in between boards need to fit together tightly, more important if being flushed than skimmed. Provided all the studs are set out to the correct centers for the size of the boards you are using and all the noggins are in place you should be able to board the wall really quickly.

Once one side is done, sound insulation like Rockwool can be fitted in between the studs before boarding up the other side.

Fixing sheets of plasterboard - Nail or screw the plasterboard to the wall/ceiling?

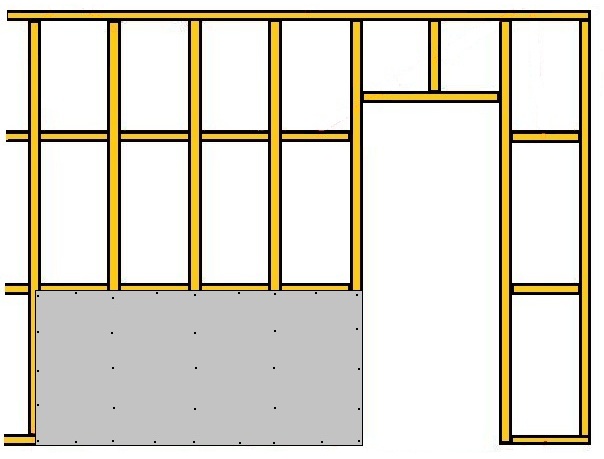

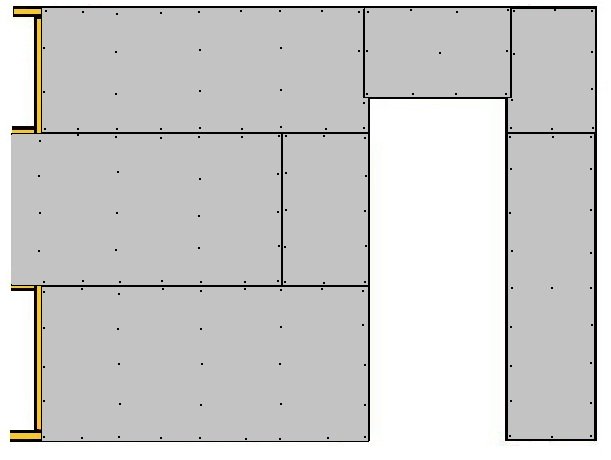

The pictures below are of a wall that is being plastered. If the joints are only being taped and jointed the boards are better installed vertically (one board from floor to ceiling) so there are only vertical joints to finish.

You can screw plasterboard to the studs with a drywall screw-gun, normal battery drill/driver or an auto-feed screw-gun. The auto-feed screwdriver

I haven't drawn a door frame in the picture, but when a board is installed it should be tight up against a door lining or other wall but half lap onto a stud and noggin where boards join, like below. Don't screw too close to the edge of the boards and no boards edge should be without timber behind it to fix to.

When fixing 1200mm wide boards (4ft), I put 5 screws (or tacks) across the width and screw into the bottom plate and noggin in between the studs too. So the screws should be no more than 250-300mm apart.

When installing the next board stagger the joints for strength wherever possible. Sometimes like above a doorway a notch needs to be cut so that the sheets all land half on a stud.

If you are cutting plasterboard in an L shape, or need to cut a corner out of a board you will need to first cut one line (I normally do the shortest) with a handsaw and the other you can scribe with a knife and snap like before. Rather than buying a saw, I just use an old hand saw. Cutting plasterboard with your best hand saw will dull the teeth really quickly and you'll soon need another one.

For perfectly round holes in plasterboard for things like spotlights and soil/waste pipes I use a plasterboard circle cutter. Alternatively you can use a jab-saw (sometimes called a pad-saw) which is also good for cutting holes for electrical cables etc. that need to be brought forward too.

Trimming & adjusting the cut for a better fit

If you need to shave a bit of the board off, when scribing to an irregular shape for example instead of cutting plasterboard with a saw or knife you can use a Surform, otherwise known as a Rasp. This tool works like a plane but has a replaceable blade that looks a bit like a cheese grater.

How to fix plasterboard - is screwing or nailing plasterboard better?

Plaster-boarding used to be called 'tacking', because boards were nailed to the studs or joists with tacks. These would often 'pop' the plaster off themselves if they weren't fixed tight to the ceiling joists or studs and the board then moved. Instead, boards are now screwed with drywall screws that almost eliminate this problem - provided they are not wound in too far. The screw heads need to finish just under flush with the surface of the board. If they are proud, not only are they not doing the job but the plasterer will catch and dent his trowel on them (then he'll probably moan like f#@k).

Extra steps to take if you are tiling onto plasterboard

Plasterboard is also a good sheet material to tile onto because it doesn't expand and contract like plywood and the adhesive can get a stringer bond compared with plywood.

Whenever I build pipe boxing's that are going to be tiled in a kitchen or bathroom for example I use 12.5mm plasterboard to cover them.

If the boxing needs more strength, I'll cover it with thin plywood first and then fix plasterboard onto that for the tiler.

What size sheets does plasterboard cmoe supplied in?

There are varying thicknesses and specifications of boards available ranging from 6-25mm (1/4in to 1inch thick).

The most commonly used boards on site are 2400x1200(8x4) and 1800x900(6x3) but longer boards (6m) are available for commercial projects. The 1800x900/600 boards are perfect for loft conversions because they can easily fit through Velux windows.

What diiferent types of plasterboard are available?

Boards with loads of different properties are available, from acoustic to fire retardant. Some wall board systems can offer up to 4 hours worth of protection from a fire (hopefully you'd be long gone by then..). 'Aqua boards' are also available that are mould resistant and can withstand high levels of moisture/ humidity, great for bathroom walls and ceilings etc.

Check out the Gyproc website here for more information and a tool to help you choose the right board for your application.

Other pages you may find useful;

Click here to see how I get a string fixing when screwing things to plasterboard

Or click here to go back to the page with more information about building stud work walls

Do you use a different method when cutting plasterboard or know of anything I've missed?

Use the comments section below,