How to use your Carpenter Square like a pro

Different types of squaring tools and their uses

You are not a cowboy, so of course you'll use a carpenter square to produce work with perfect 90° or 45° degree corners when required.

To check your squares are giving a true 90° angle mark a line on a scrap piece of timber. Then, flip the square over and check it with the other side. If it doesn't line up, it's out - bin it! Adjustable tools like the combination square are more likely to give a false reading than fixed blade tools but a god quality one will stay true for longer. It's why spending a little extra on a decent square is important, cheap ones really don't last very long.

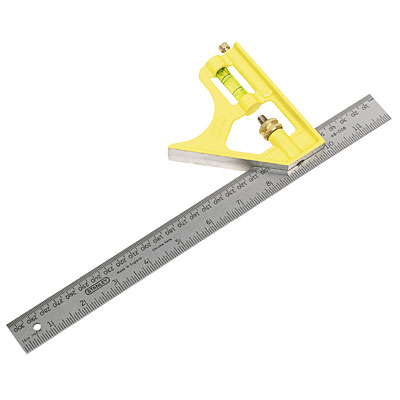

Combination Square

Without a doubt the carpenter square I use most for finish carpentry work is the Combination Square.

It is good for marking lines at 90°, 45° and 135° and with an adjustable sliding ruler that can also be used to mark a parallel line along the work piece when scribing or ripping down timber.

The adjustable ruler can also be used for measuring the depth of mortices or similar holes by placing the solid stock of the square onto the face of the timber and sliding the ruler into the mortice until it stops. Tighten the thumb screw and check the measurement (I use this method when chopping in mortice locks to check the depth).

Stanley Speed Square tips

The Stanley Quick Square 46-053 I use is really handy for lots of jobs but primarily roofing carpentry including hip rafters.

It can be used as a try square too, and also a guide when using a circular saw to cut timber perfectly square, quickly.

Because it's made of one piece of metal it's much less likely to become untrue if dropped or just over time and use. The speed square is smaller than the framing square and so more portable (fits in your pouch).

I bought the larger version of the two sizes available. When faced with two size options buying tools I tend to go for the larger. This is because I dread coming up against a job that my tools are too small for and wishing I'd spent that little bit extra when I had the chance.

Using a Tri-Square

You can use a Tri Square if you don't need an adjustable rule. Typically a tri-square is a flat steel blade riveted at exactly 90 degrees to a wooden handle, and that has a strip of brass attached to it. Traditional try squares are more accurate than combination squares when marking 90° lines because the blade is fixed in place so there's little chance of it becoming untrue.

However, they are fairly restricted to checking square and trueness. Whilst that is handy, I've got a 'Trend M3 Square With Tri-Blade & Scribe' which I bought because it has more functions than a standard one.

For example, you only need to move it once and you can mark round all four sides of the work-piece. This saves a bit of time and is especially handy when marking mortise and tenons as you need to transfer lines all the way round a work-piece. It also has a sliding marker I attach a sharp pencil to for marking parallel lines and a handy 45 degree sliding bevel style blade that's stored in the handle. Its much more useful than a standard try square!

The mighty Trend M3 square

This is an expensive carpenter square not everyone will be able to afford, I paid around £50 at Amazon.co.uk

for it.

However, if you do a lot of fine finish and second fix carpentry work like I do it's one of those '6 in 1' tools you buy and then wish you'd bought years earlier. This carpenter square is good for meeting deadlines - it knocks at least 75% off setting out time when working around all four sides of timber as you only need to move the tool once, also reducing the margin for error. The ruler has metric and imperial measurements, the bevel has angle increments marked for quick referencing. You can use the pencil attachment

to scribe a line along the timber (width/depth etc) much like a combination square. And the main blade is adjustable/re-settable if it becomes untrue.

Steel Carpenter Square

I use my framing square again for setting out roof rafters and also checking I'm building things square. It comes in handy for loads of jobs when setting out walls, boxing's, and I use it when fitting kitchens to check units are square.

Click here to go back to the main Hand Tools page

Have a comment or question about the best type of carpenter square for the job?